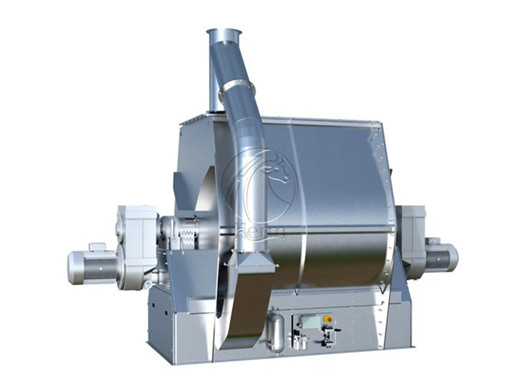

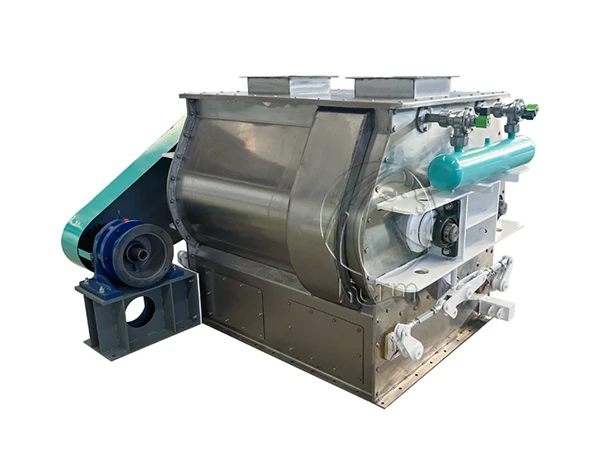

The premix feed mixer is a specialized mixing equipment designed for 1%–5% feed premix, micro-element additives, and high-precision powder materials. It is widely used in the feed, additive, food, chemical, and pharmaceutical industries, capable of rapidly, efficiently, and accurately mixing dozens or even hundreds of micro ingredients.

Featuring high mixing uniformity, short mixing time, minimal material loss, and zero cross-contamination, this machine has become a standard configuration for modern premix processing plants, feed manufacturers, and large-scale farming groups.

VIDEO

1. Superior Mixing Uniformity for Accurate Micro-Ingredient Control

Advanced paddle structure ensures multi-directional convection, shear, diffusion, and tumbling of materials.

Mixing uniformity reaches CV ≤ 3%–5% , meeting high-end premix production standards.

Capable of evenly dispersing micro ingredients with inclusion rates as low as 0.01%.

2. Fast Mixing and High Batch Efficiency

Achieves a complete and uniform mixing cycle within 45–120 seconds ;

3–5 times more efficient than traditional mixing equipment;

Significantly increases plant capacity and reduces labor waiting time.

3. Ultra-Low Residue to Prevent Cross-Contamination

Streamlined body design eliminates dead corners.

Large pneumatic discharge door ensures rapid and complete unloading.

Standard residue rate ≤ 0.1% , ideal for high-quality premix production;

An optional self-cleaning system improves hygiene standards.

4. Reliable Sealing System with Zero Dust Leakage

Equipped with reinforced sealing strips and heavy-duty locking mechanisms;

Prevents powder leakage during operation;

Creates a cleaner working environment and meets global hygiene standards.

5. Robust Structure and Long Service Life

The main body is built with high-quality welded steel.

Critical components such as bearings, reducers, and seals use reputable brands.

Ensures long service life, low maintenance requirements, and stable operation.

6. Optional Liquid-Adding System for Powder–Liquid Mixing

Supports the addition of oil, nutrient solutions, enzyme preparations, etc.;

Fine atomization nozzles ensure uniform spraying without clogging.

Meets the needs of high-end premix formulas requiring liquid additives.

7. Intelligent Control System (Optional)

PLC control with touch-screen operation;

Automated weighing, mixing, and discharge;

Can be integrated with plant management systems for real-time monitoring and batch traceability.

The premix mixer typically adopts a single-shaft or double-shaft paddle structure.

The motor drives the main shaft to rotate.

High-speed paddles lift and throw materials to create a “zero-gravity zone”;

Materials undergo rapid convection, mixing, and diffusion inside the chamber;

When the large pneumatic discharge gate opens, materials are discharged quickly with no blockage and minimal residue.

This mixing method is particularly suitable for premix formulations that contain complex ingredients and require extremely precise dosage control.

Feed Industry

1% premix

5% premix

Micro-ingredient additives

Vitamins and trace minerals

Food Industry

Powdered food materials

Nutritional fortifiers

Flavors and seasonings

Chemical Industry

Powdered chemicals

Catalysts

Pharmaceutical Industry

Pharmaceutical powder premixing

Medical excipient blending

Mixing chamber

Main shaft & paddle assembly

Feeding inlet & inspection window

Pneumatic quick-discharge gate

Drive system (motor + reducer)

Sealing system

Electrical control system

Liquid feeding system (optional)

Q1: Is this mixer suitable for micro-ingredient additives? Yes. It is ideal for ppm-level micro additives and ensures precise, uniform distribution.

Q2: Will stratification occur during mixing? No. The zero-gravity mixing technology effectively prevents material segregation.

Q3: Can this machine be used for high-value premix products? Absolutely. Its high uniformity and low-residue design make it suitable for premium premix applications.

Q4: What about installation and after-sales service? Depending on customer needs, we provide:

Complete machine delivery

On-site installation and commissioning

Long-term technical support

Global export and after-sales services

Model SHDJ0.2 SHDJ0.5 SHDJ1 SHDJ2 SHDJ3 SHDJ4 SHDJ6 Volume(m3) 0.2 0.5 1 2 3 4 6 Mixing quantity(kg) 100 250 500 1000 1500 2000 3000 Time/batch(s) 60-180 60-180 60-180 60-180 60-180 60-180 60-180 Mixed uniformity(%) ≥95 ≥95 ≥95 ≥95 ≥95 ≥95 ≥95 Power(kw) 2.2/3 5.5/7.5 11/15 18.5/22 30 37/45 55